Back to the main page

THE 10 DOLLAR EMERGENCY VENTILATOR

This document describes an easy to build, cheap emergency ventilator that uses an air mattress

pump to periodically deliver positive air pressure. It was not designed to replace a real ventilator. It

was only designed to periodically some support while waiting for a real ventilator to be available.

So build or use it at your own risk. You can’t hold me liable for anything. There are already many

DIY ventilator designs out there, but most of them rely on 3D printing and specialized electric

motors to squeeze a self inflating bag. The design I propose requires only very basic electronics

know how and uses commonly found, cheap parts to build. Nevertheless, it has a pressure limiter, a

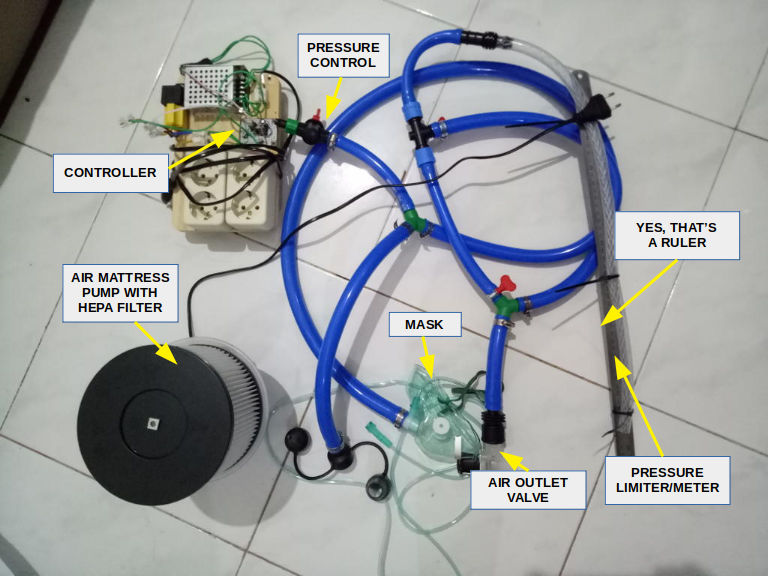

pressure control, an electronic valve, as well as an on-off timer. First off, marvel my magnificent

creation:

Fig 1: The 10 Dollar Ventilator

I. The Ventilator Pump

To build the pump, we’ll connect the air inlet of an air mattress pump with a HEPA filter to filter out

the air and remove any tiny particles that can be harmful to the user. Choose a decent air mattress

pump and a good quality cylindrical vacuum cleaner HEPA filter. Of course you can choose any

HEPA filter, but it should make our job much harder. Notice the air mattress pump and the HEPA

filter are the main components of the ventilator pump. The rest of are just there to make it happen.

To make long story short, I got lucky because the pump has some kind of plastic structure with a

hole in the middle which is perfect for tapping. I re-purposed two chopsticks, tap both sides with a

suitable die (I connected them with an empty pen refill and some epoxy). Since the diameter of the

filter is bigger than the diameter of the pump, I put a hole in the middle of a plastic plate and fit it

on the intake part of the pump before sealing everything with epoxy putty. The filter fits nicely on

top of the pump and the bolt fits really well. Seal the bolt with some patafix or tack it to close any

openings. You can also use any other means to secure the HEPA filter. Just use your imagination.

Fig 2: Building the Ventilator Pump

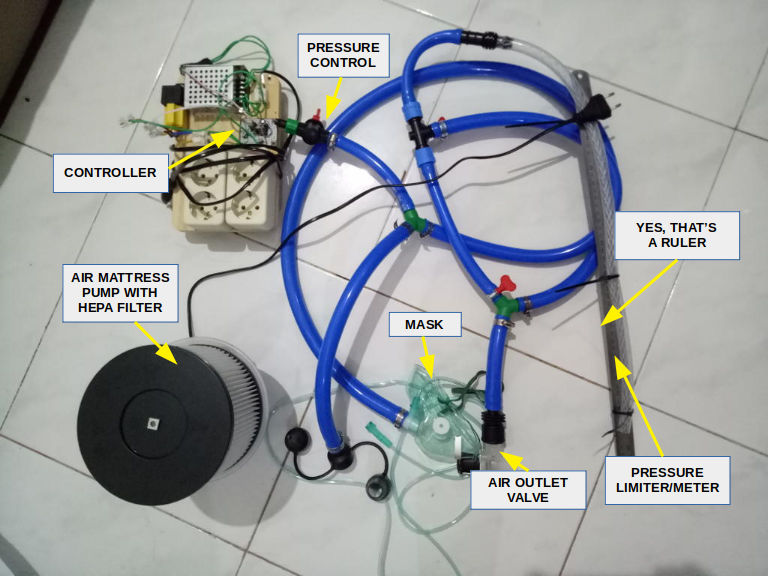

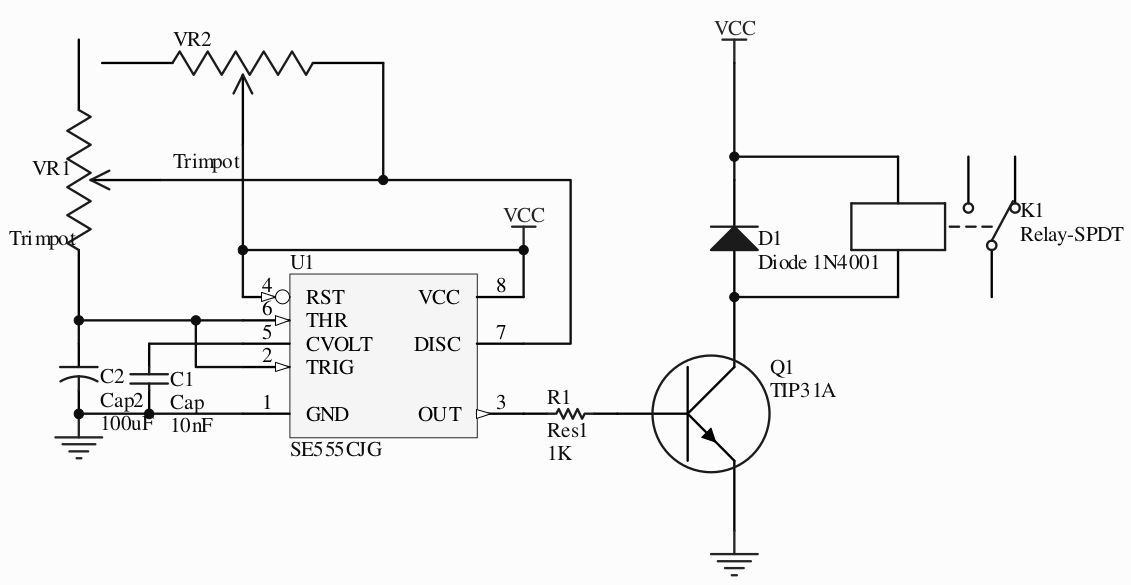

II. Controller Design

There’s no ventilator without a controller, unless you want to operate it manually. There are many

options, but in order to make it easy to assemble I decided to use a 555 chip configured as an

astable multivibrator. FYI, you can easily replace it with a two transistor flip flop. Your choice.

Fig 3. Controller Circuit Diagram

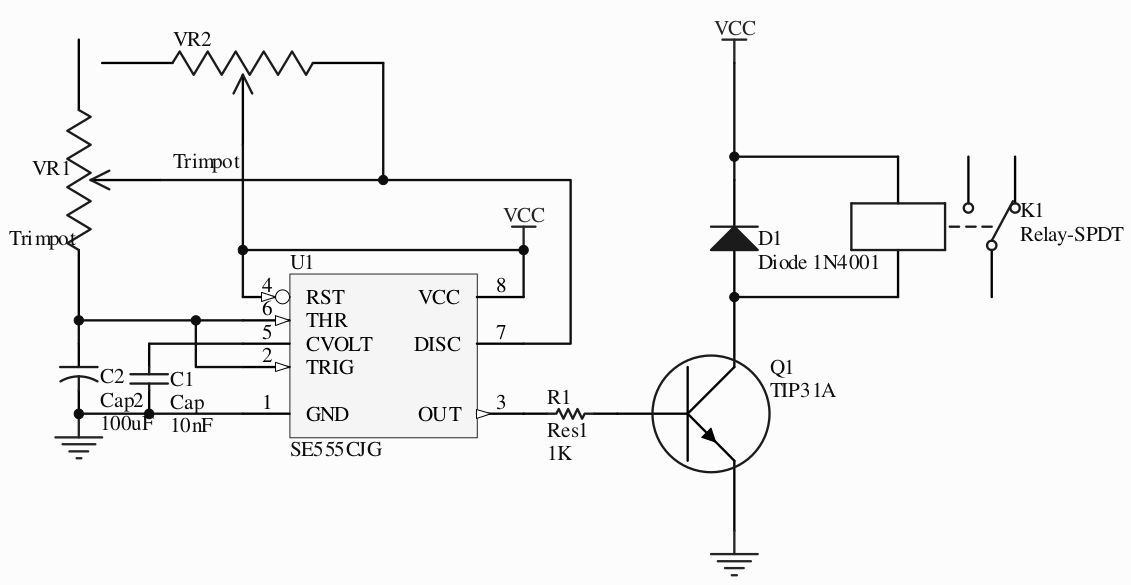

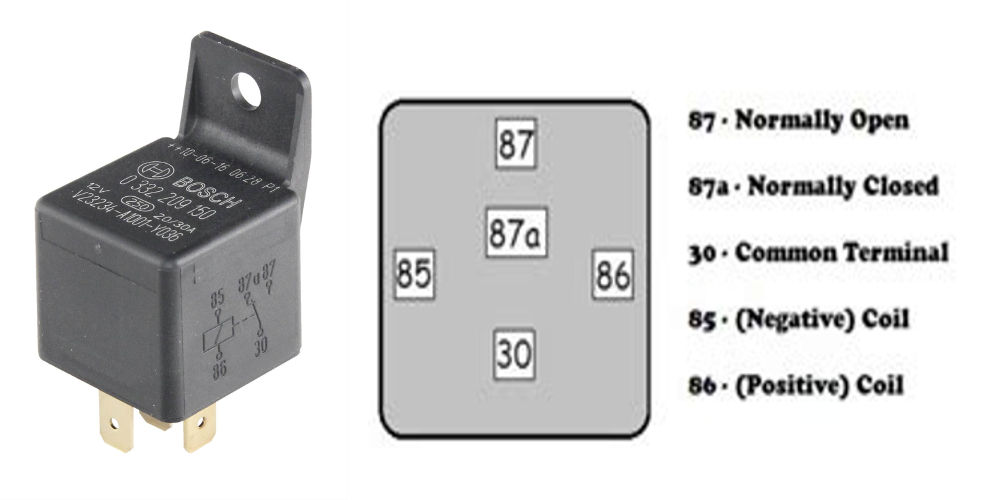

VR1 and VR2 should be 50K or 100K trimpots to give the controller some flexibility. K1 is can be

any SPDT relay, but you can probably choose an automotive relay because of the price and

performance. There are basically two types of automotive relays. One type has four terminals: It’s

SPST normally open. The other type has five terminals, and it’s SPDT with both normally open and

normally close contacts. You should choose the one with five terminals for simplicity. Buy the

socket too for convenience, just in case you need to replace it.

Fig 4. SPDT Automotive Relay (reproduced absolutely without permission)

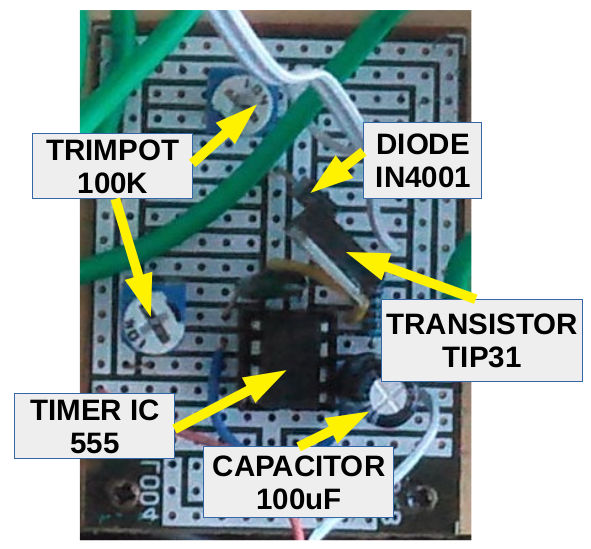

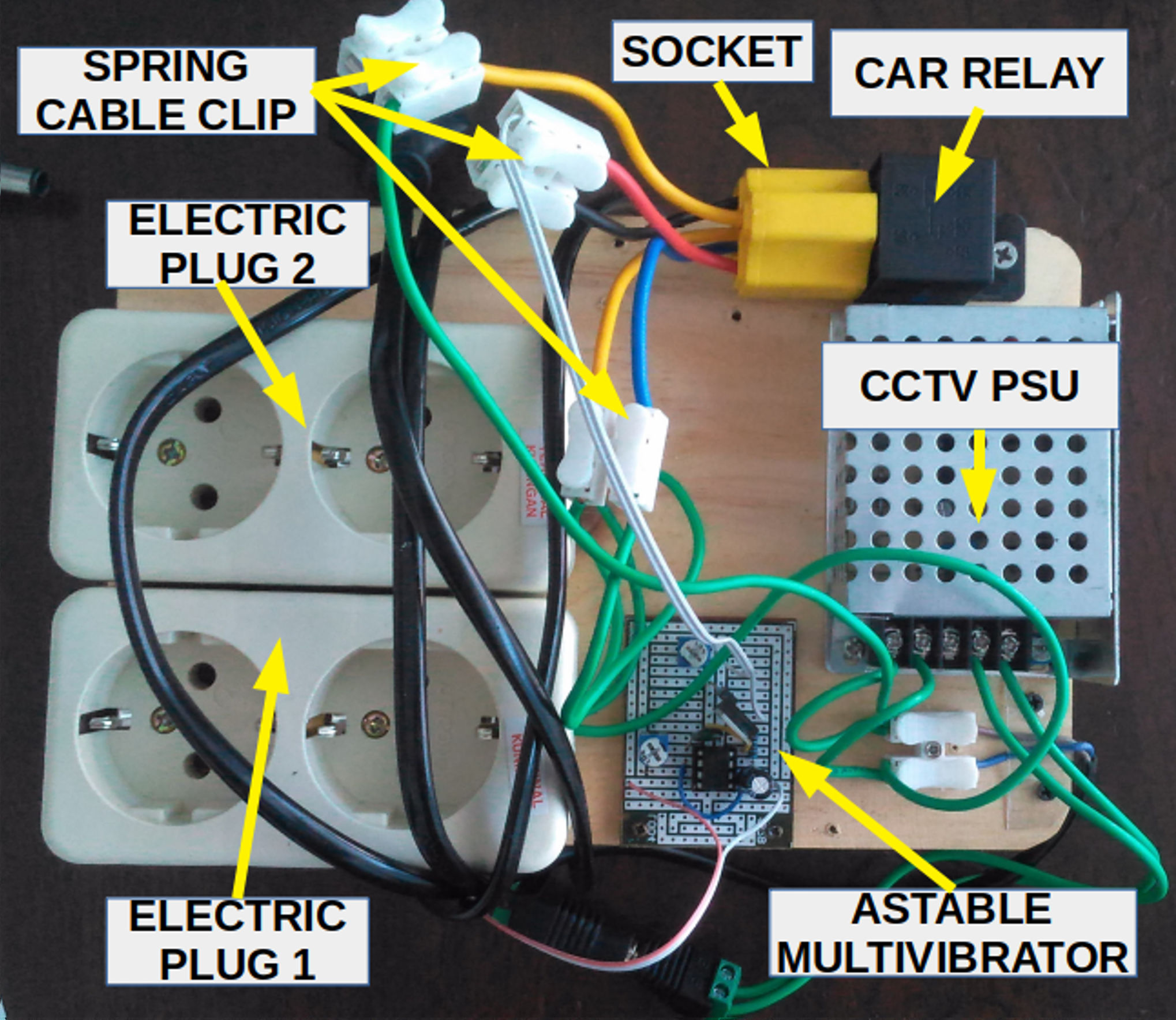

III. Building the Controller

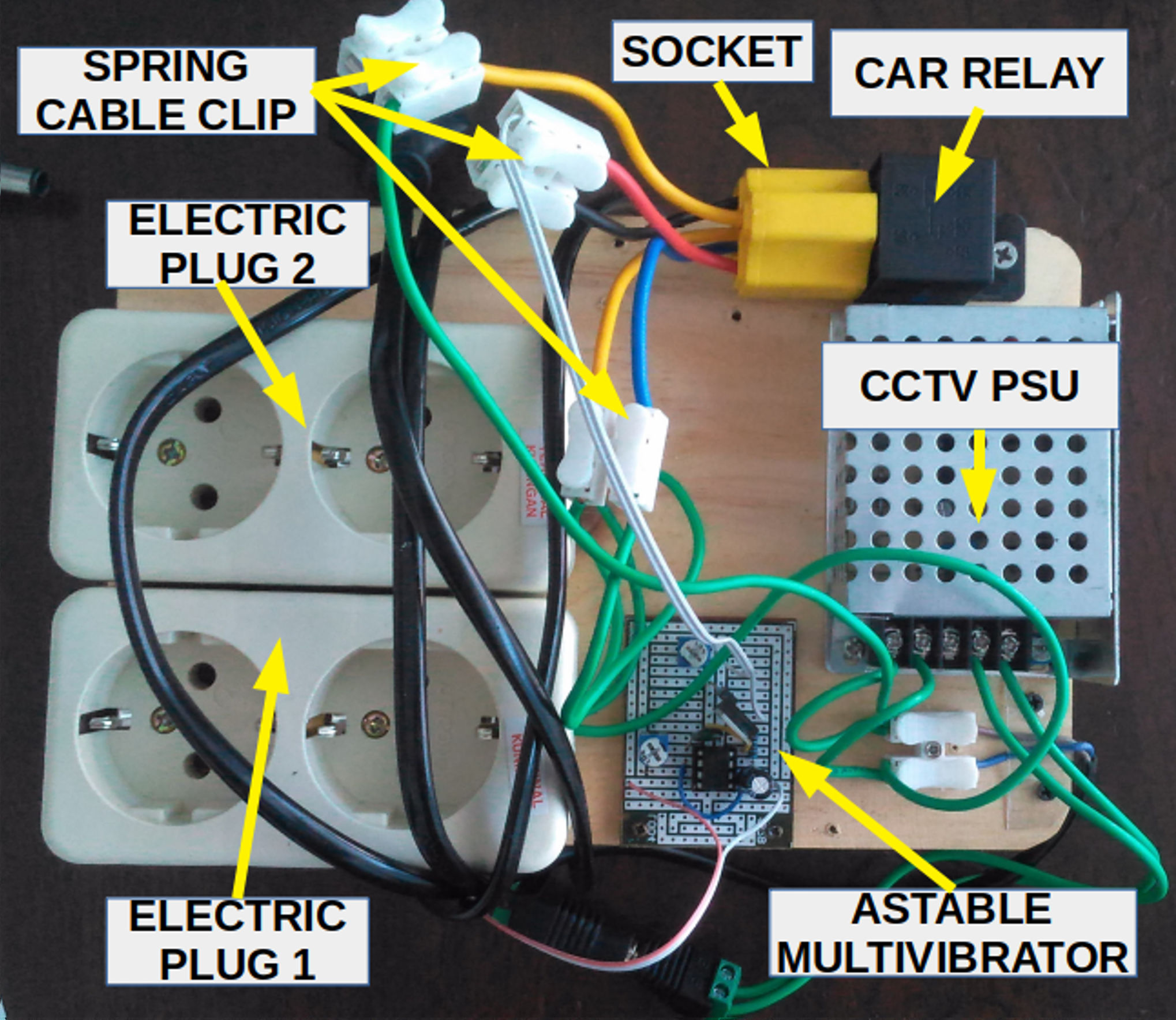

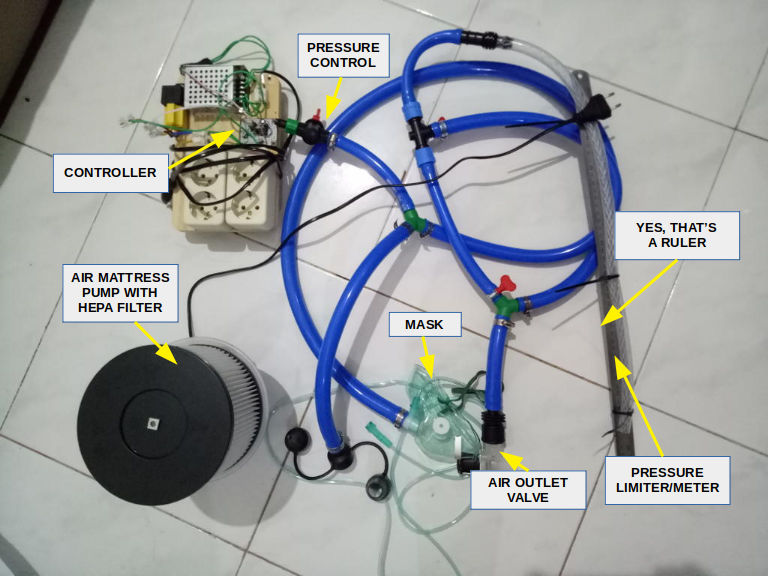

I made sure all the parts needed to build the framework are readily available everywhere. I screwed

all the parts on a wooden chopping board to make sure everything stays in place. All connections

use spring cable clips to make sure we can replace damaged parts easily. The electric outlets are

regular electric outlets commonly found at electric stores. I used a 3A CCTV power supply to

power up the circuit. The car relay is securely placed on the chopping board with a socket attached

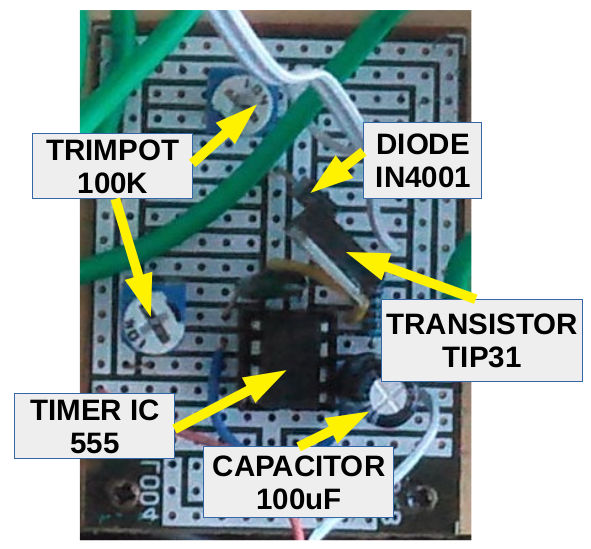

to it. I used an Elektor all purpose PCB because breadboard connections can loosen over time.

Component values are kind of loose. You can safely use a 47uF to 470uF capacitor and adjust the

value of the trimpots accordingly. If you choose a large capacitor value, you can get away with

smaller resistance. The transistor is an NPN power transistor. It can handle so much more than a

measly relay, but that was what I had at that time. The diode protect the transistor since relay is

inductive. PS: Always choose lead free, RoHS compliant parts and soldering wire.

Fig 5. The Controller Board

IV. Putting the Controller to Work

Not that we’ve finished our controller, it’s time to put it to work. Follow the wiring diagram (see

figure 6) below. The component on the right top part is an electronic valve, but we often call it a

“solenoid”. A washing machine uses one, so buy one at a spare part store or a service center. Choose

one with the correct voltage rating. There are also DC solenoids, but you have to specifically look

for one. Connect the terminals to an electric plug and you are done.

Fig 6. Wiring Diagram of The Electrical Part of the Ventilator

Here’s how it works: When the controller switches the left power socket, the pump should turn on

and deliver filtered air. When the right one is on, the solenoid should let some air out. The patient’s

lung should provide enough pressure. Figure 7 shows a fully assembled controller board.

Fig 7. A Fully Assembled Controller Board

You can also connect another pump to the solenoid to lower the air pressure for the patient can’t

exhale properly, but that’s another story.

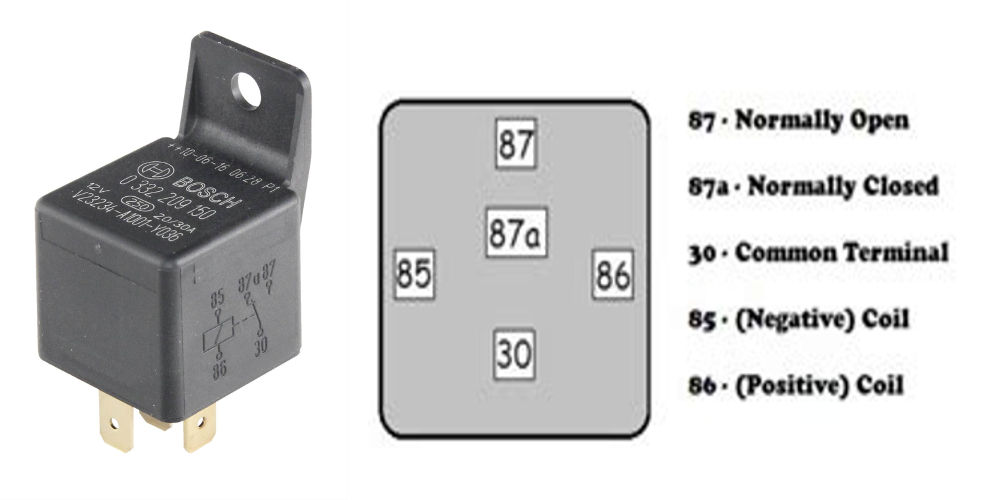

V. The Air Delivery System

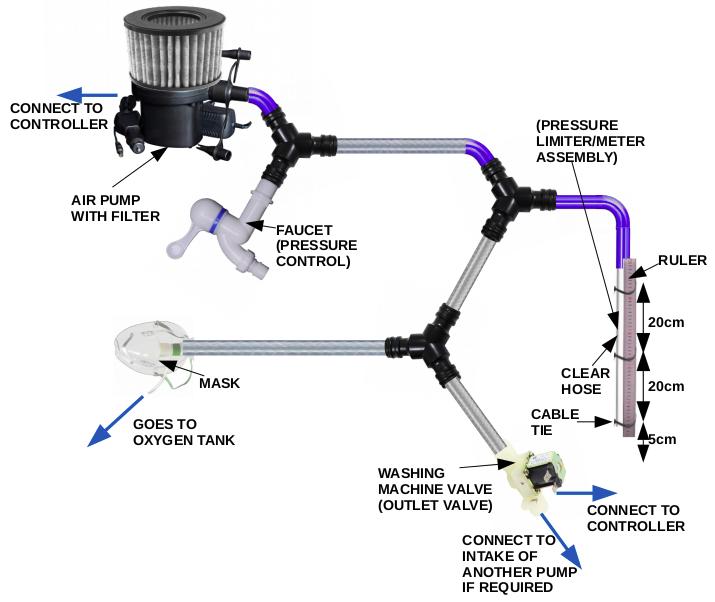

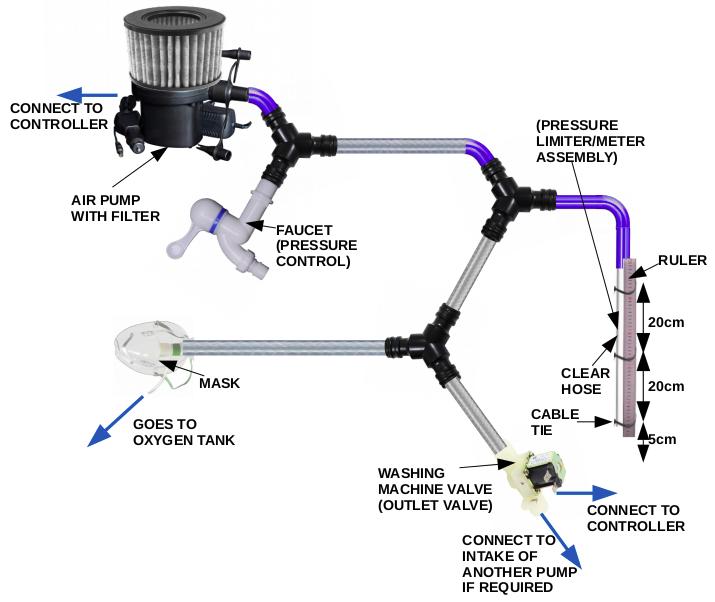

Below (figure 8) is the proposed air delivery system. It consists of a few meters of reinforced

garden hose, a segment of clear garden hose, a ruler, the pump, a washing machine valve, a faucet,

three splitters, and a mask.

V.1. Setting Up the Pressure Limiter/Meter Assembly

First, dip the pressure limiter/meter assembly into a bucket. Secure the assembly to the bucket’s handle or rim by any means necessary. I usually just First, dip the pressure limiter/meter assembly into a bucket. Secure the assembly to the bucket’s

handle or rim by any means necessary. I usually just use a cable tie. Fill the bucket with 25cm of

water (until the water level reaches the second cable tie of the pressure limiter/meter assembly).

Now fully open the faucet, and plug the air pump to electric outlet, then turn it on. Block the mask

as well, so the circuit is now fully closed. The air pump should not deliver enough pressure to push

air out from the clear hose. Slowly close the faucet until the air reaches around 15-20 centimeter

mark. You should also ask a recommendation from a medical professional when available.

V.2 Starting and Calibrating the Ventilator System

Re-adjust the trimpots to the middle, then connect the pump and the valve to the controller board

electric plug (see figure 6) and plug the board an electric outlet. The controller should turn the pump

and the valve on and off sequentially. Readjust the trimpots to the get the desired timing, and the

controller delivers a little over 12 cycles per minute. One of the trimpots determine how much

longer the “on” period of the pump compared to the “off” period. Go and experiment with it. Patch

up the holes on the mask as required. Use a duck tape if necessary. Congratulations! Your ventilator

is up and running!

Fig 8. The Air Delivery System

VI. Further Modifications

There are modifications that we can do to either improve the ventilator or to make it easier to build

with a more limited resources. Below is a list of some possible modifications.

VI.1 Not Another One!

If the user is unable to exhale, an additional air pump is in order. Simply connect the outlet valve to

a splitter, then connect the other ends of the splitter to faucet and to the inlet of the other air pump.

Plug the pump to the same outlet you connected the valve. Watch the pressure meter/limiter. Adjust

the faucet until you achieve the desired pressure.

V1.2. The Two Relays

We can easily add a PNP power transistor to the controller board. It will be active when the other

power transistor is inactive and vice versa. Connect two four terminal relays (they are easier to find)

instead of a five terminal relay. You can also use solid state relays, BTW. They are a lot more reliable

than mechanical relays.

V1.3. Totally a Miser

Instead of buying new components, you can take some components from an old amplifier. Use two

low power transistors to build a flip flop, then connect one power transistor to each side. A

transistor power amplifier should have enough parts to build this kind of controller board. Even the

power supply won’t be wasted.

VI.4. Normally Open

Most electronic valves out there are normally closed. That means it doesn’t open unless we power it

up. If the controller board fails to supply electricity for some reason, things can get ugly. Using a

normally open valve should solve this problem. Virtually all of them are made for microprocessor

projects, requires 12VDC, and three times as expensive as a washing machine valve but it’s worth it

if you can get your hands on one. Buy a cheap CCTV adapter and plug it to the pump side electric

outlet of the controller board. Plug the output to the valve.

VI.5. Too Much of a Good Thing

Remember chapter V.1? If the pump delivers too much pressure even with the faucet fully open,

connect another faucet between the pump and the splitter. Adjust this second faucet to constrict the

air flow a bit.

VII. Conditions of Use

This ventilator is an EMERGENCY ventilator. It provide bare minimum functionalities and safety

precautions. It should not be used unless there’s no other choice. Replace with a new unit regularly

before it malfunctions. Again, use it at your own risk. The first thing you should do if somebody has

trouble breathing is to seek medical help from a medical facility.

Building and using this ventilator is arranged by prayerware licensing term V1.01. After

successfully building or using this ventilator, the person involved should wish for all beings to be

happy and free from suffering, then do something really nice for someone else.

VIII. Bill Of Materials

Below is a list of the required parts to build this ventilator, including the prices. The prices listed here is based on the price of the parts you get from online stores and brick and mortar electronic stores operated by enemies of capitalism who do not to price gouge their customers.

| Part | PCs | Price each (USD) | Total (USD) |

| Air mattress pump | 1 | 3 | 3 |

| NE555 | 1 | 0.05 | 0.05 |

| Resistor | 1 | 0.01 | 0.01 |

| Trimpot | 2 | 0.02 | 0.04 |

| Tip31 transistor | 1 | 0.05 | 0.05 |

| Multipurpose PCB | 1 | 0.1 | 0.1 |

| Electrical outlets | 2 | 0.3 | 0.6 |

| Automotive relay | 1 | 0.75 | 0.75 |

| Relay socket | 1 | 0.3 | 0.3 |

| CCTV power supply unit | 1 | 1.5 | 1.5 |

| Electric plug | 3 | 0.15 | 0.15 |

| Garden hose | 5 | 0.3 | 1.5 |

| Ruler | 1 | 0.05 | 0.05 |

| Faucet | 1 | 0.3 | 0.3 |

| Hose clamp | 12 | 0.03 | 0.36 |

| Spring cable clip | 3 | 0.03 | 0.09 |

| Cable | 3 | 0.03 | 0.09 |

| Chopping board | 1 | 0.3 | 0.3 |

| HEPA filter | 1 | 1.0 | 1.0 |

| TOTAL COST | USD 10.24 |